Unlocking the Power of Quartz Piezoelectric Sensors: The Science, Innovations, and Real-World Impact Behind This Game-Changing Technology

- Introduction to Quartz Piezoelectric Sensors

- How Quartz Piezoelectric Sensors Work: The Science Explained

- Key Advantages Over Other Sensor Technologies

- Major Industrial and Commercial Applications

- Recent Innovations and Emerging Trends

- Challenges and Limitations in Current Use

- Future Prospects: What’s Next for Quartz Piezoelectric Sensors?

- Conclusion: The Lasting Impact of Quartz Piezoelectric Sensors

- Sources & References

Introduction to Quartz Piezoelectric Sensors

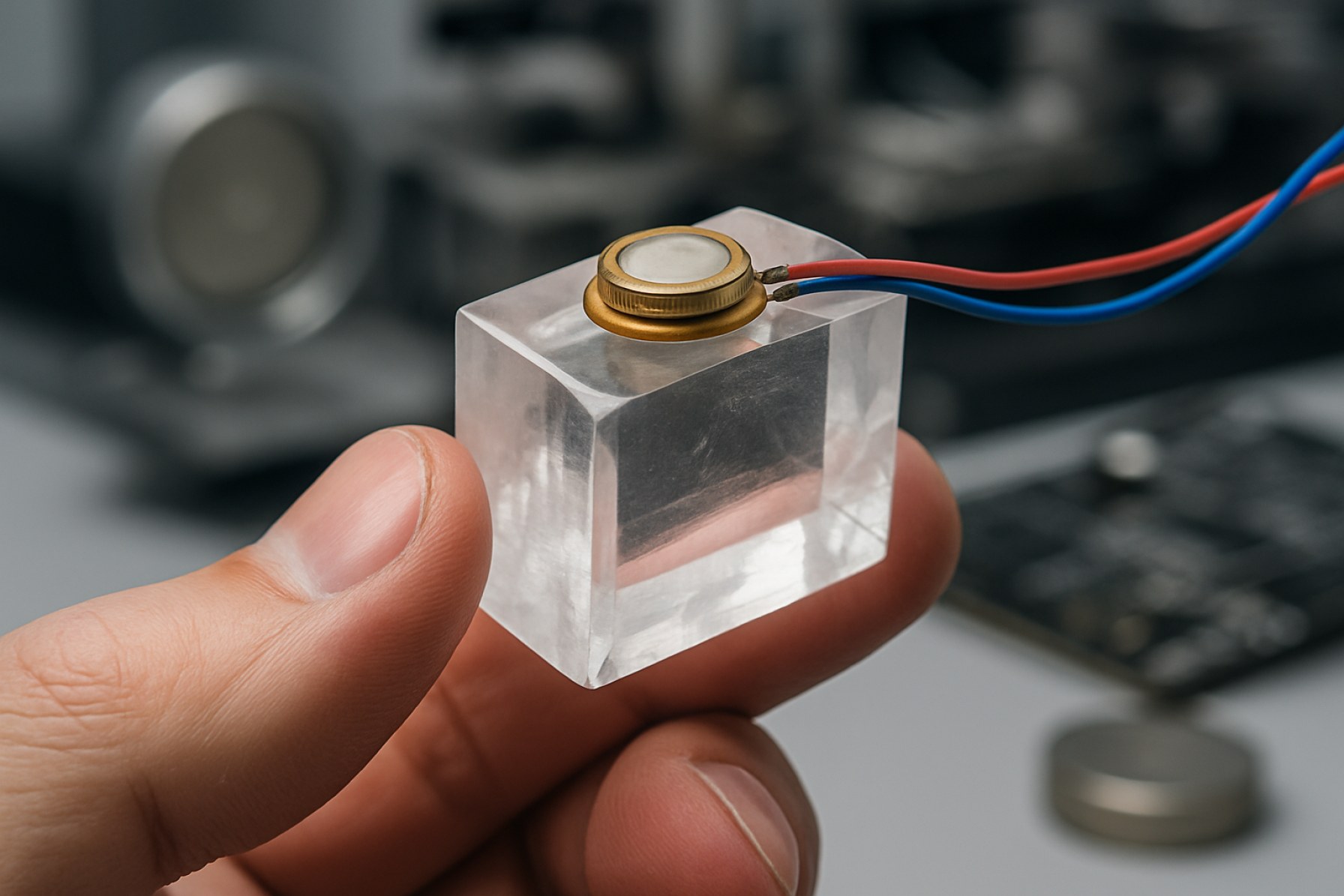

Quartz piezoelectric sensors are precision devices that exploit the unique piezoelectric properties of quartz crystals to convert mechanical stress into measurable electrical signals. This phenomenon, first discovered by the Curie brothers in the late 19th century, forms the foundation for a wide range of sensing applications. Quartz, a naturally occurring crystalline form of silicon dioxide, is particularly valued for its stable and repeatable piezoelectric response, high mechanical strength, and resistance to environmental factors such as temperature and humidity. These attributes make quartz-based sensors highly reliable for both dynamic and static measurements in demanding environments.

The core principle behind quartz piezoelectric sensors is the direct piezoelectric effect: when mechanical force is applied to a quartz crystal, it generates an electrical charge proportional to the force. This property enables the precise detection of pressure, acceleration, force, and vibration. Quartz sensors are widely used in fields such as industrial process control, automotive engineering, aerospace, and medical diagnostics, where accuracy and durability are paramount. Their ability to operate over a broad temperature range and maintain calibration over time further enhances their appeal for critical measurement tasks.

Recent advancements in sensor design and signal processing have expanded the capabilities of quartz piezoelectric sensors, enabling miniaturization and integration with digital systems. As a result, these sensors continue to play a vital role in modern instrumentation and monitoring systems, contributing to improved safety, efficiency, and performance across various industries (Omega Engineering; Analog Devices).

How Quartz Piezoelectric Sensors Work: The Science Explained

Quartz piezoelectric sensors operate based on the intrinsic piezoelectric properties of quartz crystals. When mechanical stress—such as pressure, acceleration, or force—is applied to a quartz crystal, it induces a displacement of charge within the crystal lattice, generating an electrical voltage across its surfaces. This phenomenon arises from the non-centrosymmetric structure of quartz, which lacks a center of symmetry, allowing for the direct conversion of mechanical energy into electrical energy and vice versa. The generated voltage is proportional to the magnitude and direction of the applied force, enabling precise measurement of dynamic changes in physical parameters.

The operational principle relies on the orientation of the quartz cut. Specific cuts, such as the AT-cut or BT-cut, are chosen to optimize sensitivity and temperature stability for particular applications. Electrodes are deposited on the crystal surfaces to collect the generated charge, which is then processed by high-impedance electronic circuits to produce a measurable output signal. Because quartz exhibits excellent linearity, low hysteresis, and high stability over time, these sensors are highly reliable for both static and dynamic measurements.

Quartz piezoelectric sensors are inherently self-generating, requiring no external power source for signal generation, which makes them ideal for applications where low power consumption is critical. Their rapid response time and wide frequency range further enhance their suitability for dynamic measurements, such as vibration and shock monitoring. For more detailed information on the science and engineering behind quartz piezoelectric sensors, refer to resources from the National Institute of Standards and Technology and the Institute of Electrical and Electronics Engineers.

Key Advantages Over Other Sensor Technologies

Quartz piezoelectric sensors offer several key advantages over other sensor technologies, making them highly desirable in precision measurement applications. One of the most significant benefits is their exceptional stability and repeatability. Quartz, as a single-crystal material, exhibits minimal hysteresis and negligible aging effects, ensuring consistent performance over long periods and under varying environmental conditions. This intrinsic stability is particularly valuable in applications requiring high accuracy, such as in metrology and industrial process control (OMEGA Engineering).

Another major advantage is their wide dynamic range and high sensitivity. Quartz sensors can detect extremely small changes in force, pressure, or acceleration, making them suitable for both low- and high-amplitude measurements. Their high natural frequency allows for rapid response times, which is critical in dynamic measurements such as vibration analysis and impact testing (Kistler Group).

Quartz piezoelectric sensors are also inherently robust against electromagnetic interference (EMI) and can operate reliably in harsh environments, including extreme temperatures and high-pressure conditions. Unlike capacitive or resistive sensors, they do not require external power for signal generation, reducing system complexity and potential points of failure (Brüel & Kjær).

In summary, the unique material properties of quartz confer superior long-term stability, sensitivity, and environmental resilience, positioning quartz piezoelectric sensors as a preferred choice for demanding measurement tasks across various industries.

Major Industrial and Commercial Applications

Quartz piezoelectric sensors are integral to a wide range of industrial and commercial applications due to their high sensitivity, stability, and reliability. In the automotive industry, these sensors are extensively used for engine knock detection, fuel injection monitoring, and vibration analysis, contributing to improved engine performance and reduced emissions. The aerospace sector employs quartz piezoelectric sensors for structural health monitoring, vibration measurement, and pressure sensing in both aircraft and spacecraft, ensuring safety and operational efficiency. In manufacturing, these sensors are crucial for process control, quality assurance, and machinery diagnostics, where they detect minute changes in force, pressure, or acceleration, enabling predictive maintenance and minimizing downtime.

Commercially, quartz piezoelectric sensors are found in medical devices such as ultrasound imaging systems and infusion pumps, where their precision and responsiveness are vital for patient safety and diagnostic accuracy. They are also used in consumer electronics, including microphones, touch-sensitive devices, and wearable fitness trackers, leveraging their ability to convert mechanical stress into electrical signals with minimal drift over time. Additionally, the oil and gas industry utilizes these sensors for downhole pressure and vibration monitoring, which is essential for safe and efficient drilling operations. The robustness and long-term stability of quartz make it particularly suitable for harsh environments and applications requiring continuous, accurate measurements over extended periods Omega Engineering, Kistler Group.

Recent Innovations and Emerging Trends

Recent innovations in quartz piezoelectric sensors are driven by advancements in materials science, microfabrication, and signal processing technologies. One significant trend is the miniaturization of sensors through microelectromechanical systems (MEMS) technology, enabling the integration of quartz piezoelectric elements into compact, high-performance devices for applications in medical diagnostics, environmental monitoring, and wearable electronics. These MEMS-based sensors offer enhanced sensitivity, lower power consumption, and improved reliability compared to traditional designs IEEE.

Another emerging trend is the development of multifunctional sensors that combine piezoelectric sensing with other modalities, such as temperature or humidity detection, within a single device. This integration is particularly valuable in the Internet of Things (IoT) ecosystem, where real-time, multi-parameter monitoring is essential for smart infrastructure and industrial automation National Institute of Standards and Technology (NIST).

Additionally, research is focusing on enhancing the frequency stability and noise immunity of quartz piezoelectric sensors, making them more suitable for precision applications such as atomic force microscopy and high-resolution mass sensing. Innovations in surface modification and electrode design are also improving the durability and chemical resistance of these sensors, expanding their use in harsh environments, including aerospace and deep-sea exploration NASA.

Looking forward, the integration of artificial intelligence and machine learning algorithms with quartz piezoelectric sensor data is expected to enable advanced pattern recognition and predictive maintenance capabilities, further broadening their application scope in smart systems and autonomous technologies Massachusetts Institute of Technology (MIT).

Challenges and Limitations in Current Use

Despite their widespread application and high sensitivity, quartz piezoelectric sensors face several challenges and limitations that impact their broader adoption and performance. One significant limitation is their sensitivity to temperature variations. Quartz crystals exhibit temperature-dependent frequency shifts, which can introduce measurement errors in environments with fluctuating or extreme temperatures. While temperature compensation techniques exist, they add complexity and cost to sensor design and calibration OMEGA Engineering.

Another challenge is the fragility of quartz crystals. Mechanical shock, vibration, or improper mounting can cause microcracks or fractures, leading to sensor failure or degraded performance. This restricts their use in harsh or high-impact environments unless additional protective measures are implemented AZoSensors.

Quartz piezoelectric sensors also have limitations in measuring static or very low-frequency signals. Due to their inherent AC-coupled nature, they are best suited for dynamic measurements, such as vibration or pressure changes, rather than static loads. This restricts their applicability in scenarios where long-term or static force monitoring is required Kistler Group.

Finally, the miniaturization of quartz sensors poses manufacturing challenges. As device dimensions shrink, maintaining crystal quality and consistent piezoelectric properties becomes increasingly difficult, potentially affecting sensor reliability and repeatability. These challenges highlight the need for ongoing research and development to expand the operational range and robustness of quartz piezoelectric sensors.

Future Prospects: What’s Next for Quartz Piezoelectric Sensors?

The future of quartz piezoelectric sensors is poised for significant advancement, driven by ongoing innovations in materials science, microfabrication, and digital integration. As industries demand higher sensitivity, miniaturization, and multifunctionality, research is focusing on enhancing the intrinsic properties of quartz and integrating it with emerging technologies. For instance, the development of microelectromechanical systems (MEMS) based on quartz piezoelectricity is enabling the creation of ultra-small, highly sensitive sensors suitable for biomedical implants, environmental monitoring, and wearable devices. These MEMS sensors offer low power consumption and high stability, making them ideal for next-generation applications National Institute of Standards and Technology.

Another promising direction is the integration of quartz sensors with wireless and Internet of Things (IoT) platforms. This allows real-time data acquisition and remote monitoring, expanding their utility in smart infrastructure, industrial automation, and predictive maintenance. Advances in signal processing and machine learning are also enhancing the interpretation of sensor data, enabling more accurate diagnostics and adaptive control systems Institute of Electrical and Electronics Engineers.

Furthermore, research into novel quartz composites and hybrid materials aims to overcome current limitations in temperature range, frequency response, and mechanical robustness. As sustainability becomes a priority, efforts are underway to develop eco-friendly manufacturing processes and recyclable sensor components. Overall, the convergence of material innovation, digital connectivity, and intelligent analytics is set to redefine the capabilities and applications of quartz piezoelectric sensors in the coming decade Elsevier.

Conclusion: The Lasting Impact of Quartz Piezoelectric Sensors

Quartz piezoelectric sensors have established themselves as indispensable components across a wide spectrum of scientific, industrial, and consumer applications. Their unique combination of high sensitivity, stability, and reliability has enabled precise measurement and control in fields ranging from automotive engineering to medical diagnostics and environmental monitoring. The inherent properties of quartz—such as its excellent linearity, low hysteresis, and resistance to aging—ensure that these sensors deliver consistent performance even under demanding conditions. This has led to their widespread adoption in critical systems, including aerospace instrumentation and seismic monitoring, where accuracy and durability are paramount.

The ongoing evolution of quartz piezoelectric sensor technology continues to drive innovation. Advances in microfabrication and signal processing have expanded their capabilities, allowing for miniaturization and integration into complex electronic systems. As industries increasingly demand real-time, high-precision data, the role of quartz sensors is set to grow further, supporting the development of smarter, more responsive technologies. Their contribution to safety, efficiency, and quality control underscores their lasting impact on modern society.

Looking ahead, the robust performance and adaptability of quartz piezoelectric sensors position them as foundational elements in the next generation of sensing solutions. Their enduring relevance is a testament to the remarkable properties of quartz and the ingenuity of sensor engineering, ensuring that they will remain at the forefront of measurement technology for years to come (Omega Engineering, Kistler Group).

Sources & References

- Analog Devices

- National Institute of Standards and Technology

- Institute of Electrical and Electronics Engineers

- Brüel & Kjær

- NASA

- Massachusetts Institute of Technology (MIT)

- AZoSensors

- Elsevier