Unlocking Unprecedented Sensitivity: How Quartz Tuning Fork Sensors Revolutionize Scanning Probe Microscopy for Nanoscale Imaging and Force Detection

- Introduction to Quartz Tuning Fork Sensors

- Principles of Operation in Scanning Probe Microscopy

- Advantages Over Conventional Cantilever Sensors

- Sensor Design and Fabrication Techniques

- Integration with Atomic Force Microscopy (AFM) and Other Modalities

- Signal Detection and Noise Reduction Strategies

- Applications in High-Resolution Imaging and Force Spectroscopy

- Challenges and Limitations

- Recent Innovations and Future Directions

- Sources & References

Introduction to Quartz Tuning Fork Sensors

Quartz tuning fork (QTF) sensors have become indispensable components in the field of scanning probe microscopy (SPM), offering a unique combination of high sensitivity, mechanical stability, and low power consumption. Originally developed for timekeeping in watches, QTFs are now widely utilized as force sensors in various SPM techniques, including atomic force microscopy (AFM) and scanning near-field optical microscopy (SNOM). Their piezoelectric nature allows for precise detection of minute forces and displacements, making them ideal for probing surfaces at the nanoscale.

The fundamental advantage of QTF sensors lies in their high quality factor (Q-factor), which enables exceptional frequency stability and sensitivity to external perturbations. When integrated into SPM setups, QTFs can operate in both ambient and cryogenic environments, and their self-sensing capability eliminates the need for external optical detection systems. This not only simplifies the experimental setup but also reduces noise and enhances spatial resolution. Furthermore, the compact size and robustness of QTFs facilitate their use in challenging environments, such as ultra-high vacuum or low-temperature conditions.

Recent advancements have expanded the application of QTF sensors beyond traditional SPM, enabling new measurement modalities and improved imaging performance. Their versatility and reliability continue to drive innovation in nanoscale characterization, making them a cornerstone technology in modern surface science and nanotechnology research. For a comprehensive overview of their properties and applications, refer to resources provided by the National Institute of Standards and Technology and the American Physical Society.

Principles of Operation in Scanning Probe Microscopy

Quartz tuning fork (QTF) sensors have become integral components in scanning probe microscopy (SPM) due to their exceptional mechanical stability, high quality factor (Q), and self-sensing capabilities. The fundamental principle of operation relies on the piezoelectric effect inherent to quartz: when the prongs of the tuning fork oscillate, mechanical deformation generates an electrical signal proportional to the displacement. In SPM, a sharp tip is typically attached to one prong of the tuning fork, allowing the sensor to interact with the sample surface at the nanoscale.

During operation, the QTF is driven at or near its resonance frequency, and its oscillatory motion is monitored either by measuring the current generated by the piezoelectric effect or by detecting changes in the resonance characteristics. As the tip approaches the sample, tip-sample interactions—such as van der Waals forces, electrostatic forces, or magnetic forces—alter the resonance frequency and amplitude of the tuning fork. These changes are detected with high sensitivity, enabling precise mapping of surface topography and material properties.

A key advantage of QTF sensors is their ability to operate in both ambient and cryogenic environments, as well as in vacuum, without the need for optical detection systems. This makes them particularly suitable for applications where space is limited or optical access is challenging. Furthermore, the high Q factor of quartz tuning forks ensures low thermal noise and high force sensitivity, which are critical for achieving atomic or molecular resolution in SPM techniques such as non-contact atomic force microscopy (nc-AFM) and scanning near-field optical microscopy (SNOM) National Institute of Standards and Technology, American Physical Society.

Advantages Over Conventional Cantilever Sensors

Quartz tuning fork (QTF) sensors offer several distinct advantages over conventional cantilever sensors in scanning probe microscopy (SPM), making them increasingly popular for high-resolution and specialized applications. One of the primary benefits is their inherent self-sensing capability. Unlike traditional cantilevers, which often require external optical detection systems to monitor deflection, QTFs utilize the piezoelectric effect of quartz to directly convert mechanical oscillations into electrical signals. This eliminates the need for complex optical setups, reducing system size, alignment challenges, and susceptibility to environmental noise National Institute of Standards and Technology.

Another significant advantage is the high quality factor (Q-factor) of quartz tuning forks, especially under vacuum or low-temperature conditions. High Q-factors result in sharper resonance peaks, enabling more sensitive force detection and improved signal-to-noise ratios. This is particularly beneficial for applications such as non-contact atomic force microscopy (nc-AFM), where minute force gradients must be resolved American Physical Society.

QTF sensors also exhibit excellent mechanical and thermal stability due to the intrinsic properties of quartz. Their frequency stability and low drift make them suitable for long-term measurements and operation in challenging environments, including ultra-high vacuum and cryogenic temperatures. Furthermore, the compact geometry of tuning forks allows for easier integration into multi-probe systems and facilitates measurements in confined spaces where traditional cantilevers may not fit Elsevier.

Collectively, these advantages position quartz tuning fork sensors as a robust and versatile alternative to conventional cantilever-based sensors in advanced SPM techniques.

Sensor Design and Fabrication Techniques

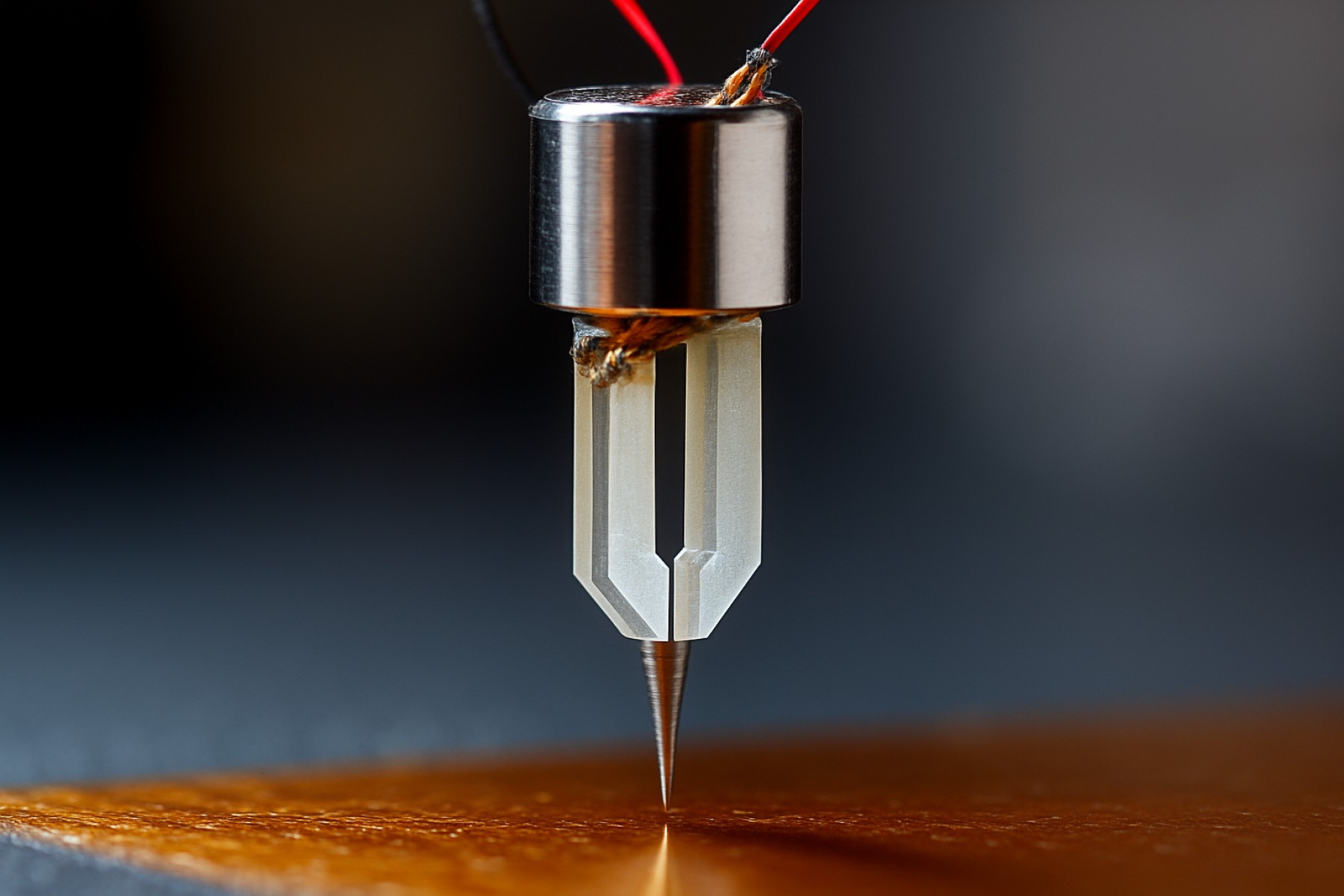

The design and fabrication of quartz tuning fork (QTF) sensors for scanning probe microscopy (SPM) are critical to achieving high sensitivity, stability, and spatial resolution. QTFs are typically fabricated from high-purity quartz using photolithographic and wet etching techniques, which ensure precise control over the fork’s geometry and mechanical properties. The standard QTF consists of two prongs with a well-defined resonance frequency, commonly 32.768 kHz, chosen for its low energy dissipation and high quality factor (Q-factor) at room and cryogenic temperatures. The electrodes are deposited onto the prongs via vacuum evaporation or sputtering, enabling the piezoelectric detection of oscillations induced by tip-sample interactions.

For SPM applications, a sharp metallic or semiconductor tip is attached to one prong of the tuning fork, often using focused ion beam (FIB) micromanipulation or precision gluing under a microscope. The attachment process must minimize mass loading and maintain the symmetry of the fork to preserve its high Q-factor and sensitivity. In some advanced designs, the tip is fabricated directly onto the prong using electron beam deposition, further enhancing mechanical stability and reproducibility. The integration of QTFs into SPM setups also requires careful electrical isolation and mechanical decoupling to reduce noise and cross-talk.

Recent advances in microfabrication have enabled the production of miniaturized and batch-fabricated QTF sensors, facilitating their use in multi-probe and high-throughput SPM systems. These developments have been instrumental in expanding the versatility and performance of QTF-based sensors in nanoscale imaging and force spectroscopy applications (National Institute of Standards and Technology; American Physical Society).

Integration with Atomic Force Microscopy (AFM) and Other Modalities

The integration of quartz tuning fork (QTF) sensors with Atomic Force Microscopy (AFM) and other scanning probe modalities has significantly expanded the versatility and sensitivity of nanoscale measurements. In AFM, QTFs are often employed in the so-called “qPlus” configuration, where one prong of the tuning fork is fixed and the other is attached to a sharp tip. This setup enables high force sensitivity and low thermal noise, making it particularly advantageous for non-contact and ultra-high vacuum AFM applications. The inherent piezoelectric properties of QTFs allow for direct electrical readout of oscillation amplitude and frequency shifts, eliminating the need for optical detection systems and thus simplifying the instrument design and reducing noise sources attocube systems AG.

Beyond AFM, QTF sensors have been successfully integrated with other scanning probe techniques, such as Scanning Tunneling Microscopy (STM) and Scanning Near-field Optical Microscopy (SNOM). In combined AFM/STM systems, the QTF can simultaneously measure topography and tunneling current, enabling correlated studies of surface structure and electronic properties at the atomic scale Bruker Corporation. The compactness and robustness of QTF-based sensors also facilitate their use in challenging environments, including low temperatures and high magnetic fields. Furthermore, the modularity of QTF integration allows for the development of multi-modal probes, where mechanical, electrical, and optical signals can be acquired concurrently, broadening the scope of scanning probe microscopy for advanced materials research Oxford Instruments.

Signal Detection and Noise Reduction Strategies

Signal detection and noise reduction are critical for maximizing the performance of quartz tuning fork (QTF) sensors in scanning probe microscopy (SPM). The QTF’s high quality factor (Q-factor) enables sensitive detection of minute forces, but also makes the system susceptible to environmental and electronic noise. To extract meaningful signals, lock-in amplification is commonly employed, allowing selective detection of the oscillation frequency while rejecting out-of-band noise. This technique enhances the signal-to-noise ratio (SNR) by demodulating the QTF response at its resonance frequency, which is typically in the tens to hundreds of kilohertz range National Institute of Standards and Technology.

Mechanical isolation is another essential strategy. Vibration-damping platforms and acoustic enclosures are used to shield the SPM setup from external disturbances. Additionally, electrical noise is minimized by careful grounding, shielding of cables, and the use of low-noise preamplifiers. Temperature fluctuations, which can shift the resonance frequency of the QTF, are mitigated through environmental control and, in some cases, active temperature stabilization American Physical Society.

Advanced signal processing methods, such as digital filtering and real-time feedback loops, further suppress noise and stabilize the QTF oscillation amplitude and phase. These strategies collectively enable high-resolution imaging and force measurements, even in challenging environments. The ongoing development of low-noise electronics and improved mechanical isolation continues to push the sensitivity limits of QTF-based SPM systems Institute of Electrical and Electronics Engineers.

Applications in High-Resolution Imaging and Force Spectroscopy

Quartz tuning fork (QTF) sensors have become indispensable in scanning probe microscopy (SPM) for applications demanding high-resolution imaging and precise force spectroscopy. Their exceptional mechanical stability, high quality factor (Q), and low thermal drift enable sensitive detection of minute tip-sample interactions, even under challenging conditions such as ultra-high vacuum or low temperatures. In atomic force microscopy (AFM) and scanning tunneling microscopy (STM), QTF sensors are often employed in the so-called “qPlus” configuration, where one prong is fixed and the other is functionalized with a sharp tip. This setup allows for simultaneous topographical imaging and force measurement with sub-nanometer spatial resolution and piconewton force sensitivity Bielefeld University.

In high-resolution imaging, QTF sensors facilitate the visualization of atomic and molecular structures on surfaces, including the mapping of chemical bonds and charge distributions. Their high stiffness minimizes snap-to-contact events, allowing stable operation in non-contact and frequency-modulation modes, which are crucial for resolving delicate surface features Nature Nanotechnology. In force spectroscopy, QTF-based probes enable quantitative measurements of interaction forces, such as van der Waals, electrostatic, and chemical bonding forces, by monitoring frequency shifts or amplitude changes as the tip approaches the sample. This capability is vital for characterizing material properties at the nanoscale, including elasticity, adhesion, and energy dissipation Elsevier.

Overall, the integration of quartz tuning fork sensors in SPM has significantly advanced the field of nanoscience, providing robust tools for both imaging and force measurement at unprecedented spatial and force resolutions.

Challenges and Limitations

Despite their widespread adoption in scanning probe microscopy (SPM), quartz tuning fork (QTF) sensors present several challenges and limitations that can impact measurement accuracy and experimental flexibility. One primary issue is the relatively high mechanical quality factor (Q-factor) of QTFs, which, while beneficial for sensitivity, can lead to slow response times and increased susceptibility to environmental vibrations. This can complicate fast imaging or dynamic measurements, particularly in ambient or liquid environments where damping is significant. Additionally, the asymmetrical geometry of QTFs, especially when a probe tip is attached to one prong, can introduce mode splitting and reduce the predictability of oscillation behavior, potentially affecting force sensitivity and spatial resolution.

Another limitation arises from the electrical properties of QTFs. Their piezoelectric nature enables self-sensing, but also makes them sensitive to electromagnetic interference and temperature fluctuations, which can introduce noise and drift in the signal. The integration of QTFs with SPM setups often requires careful electrical shielding and temperature control to maintain measurement stability. Furthermore, the attachment of tips—whether metallic, insulating, or functionalized—can be technically challenging and may degrade the Q-factor or alter the resonance frequency, necessitating frequent recalibration and limiting reproducibility between experiments.

Finally, while QTFs are robust and cost-effective, their performance in ultra-high vacuum or at cryogenic temperatures can be compromised by outgassing or changes in material properties. These factors collectively underscore the need for ongoing optimization in sensor design and experimental protocols, as highlighted by organizations such as the National Institute of Standards and Technology and the American Physical Society.

Recent Innovations and Future Directions

Recent years have witnessed significant advancements in the design and application of quartz tuning fork (QTF) sensors within scanning probe microscopy (SPM), driven by the demand for higher sensitivity, stability, and versatility. One notable innovation is the integration of QTFs with advanced microfabrication techniques, enabling the production of miniaturized and highly reproducible sensors. These developments have facilitated the use of QTFs in ultra-high vacuum and low-temperature environments, expanding their applicability to atomic-scale imaging and spectroscopy Nature Publishing Group.

Another emerging trend is the functionalization of QTF tips with specialized coatings or nanostructures, which enhances their selectivity and sensitivity for specific interactions, such as magnetic, electrical, or chemical forces. This has opened new avenues for multi-modal SPM, where simultaneous mapping of different physical properties is possible Elsevier. Additionally, the development of self-sensing and self-actuating QTFs has reduced the complexity of SPM setups by eliminating the need for external optical detection systems, thus improving robustness and ease of use MDPI.

Looking forward, future directions include the integration of QTF sensors with machine learning algorithms for real-time data analysis and adaptive control, as well as the exploration of novel materials for QTF fabrication to further enhance performance. These innovations are expected to push the boundaries of SPM, enabling new discoveries in nanoscience and materials research.

Sources & References

- National Institute of Standards and Technology

- Elsevier

- attocube systems AG

- Bruker Corporation

- Oxford Instruments

- Institute of Electrical and Electronics Engineers

- Bielefeld University

- Nature Nanotechnology